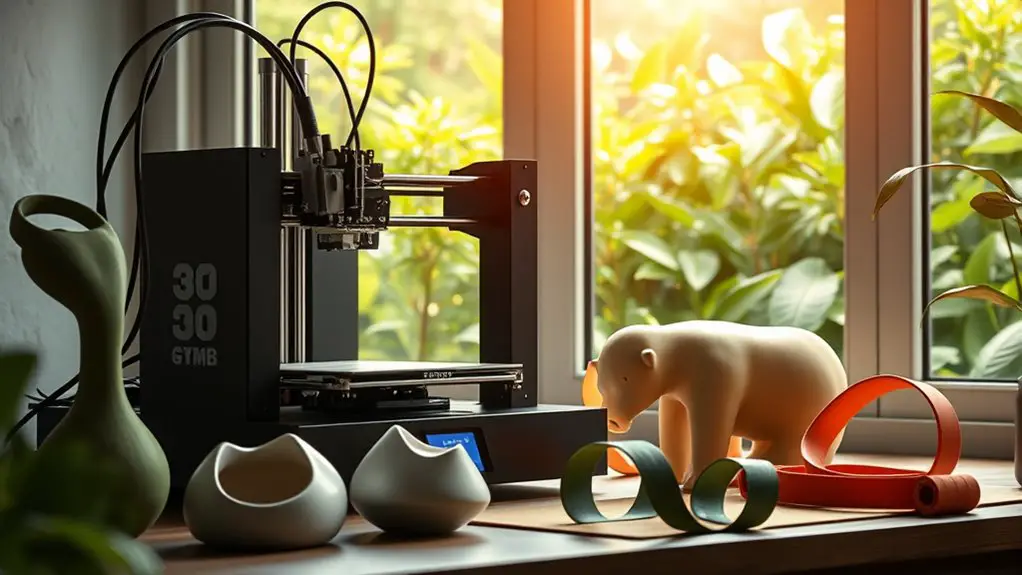

The Role of 3D Printing in Gym Equipment Development

3D printing’s revolutionizing gym equipment development by enabling customized designs that enhance your workout experience. It combines functionality with aesthetic appeal, allowing you to enjoy personalized gear tailored to your unique body specifications. With rapid prototyping, manufacturers can quickly test new concepts and make improvements, all while reducing costs. However, challenges like material limitations exist. Explore how the future of 3D printing can change the landscape of fitness equipment design and user interaction.

The Evolution of Gym Equipment Design

As gym enthusiasts have sought more effective ways to enhance their workouts, the design of gym equipment has evolved dramatically over the years. Historical advancements in materials and technology have led to equipment that’s not only more functional but also visually appealing. You’ve likely noticed how today’s machines combine ergonomic design with sleek aesthetics, making them more inviting in any gym setting.

In earlier times, gym equipment was often bulky and less efficient, primarily focused on functionality. However, modern designs consider user experience, incorporating features like adjustable settings and smart technology. These improvements don’t just enhance performance; they also reflect changing trends in fitness culture, where aesthetics matter as much as effectiveness. Whether it’s colorful weights or streamlined cardio machines, today’s designs cater to your desire for both aesthetics and performance, making your workout environment more enjoyable and inspiring. Additionally, regular exercise is beneficial for youth, helping to reduce stress, improve concentration, enhance sleep quality, and boost energy levels.

Benefits of 3D Printing in Fitness Gear

While traditional manufacturing methods often limit customization, 3D printing revolutionizes the way fitness gear is developed, offering numerous benefits that cater to individual needs. One major advantage is how quickly you can integrate user feedback into design iterations. With 3D printing, adjustments can be made swiftly, allowing manufacturers to respond to customer insights and preferences almost in real time. This technology integration not only accelerates the design process but also guarantees that the final product aligns closely with what users want.

Additionally, 3D printing allows for the creation of lightweight, durable materials that enhance performance. You can enjoy gear that feels tailored to your workouts, improving both comfort and effectiveness. By embracing this innovative technology, fitness companies can produce equipment that meets diverse requirements, paving the way for a more personalized fitness experience. Ultimately, the benefits of 3D printing in fitness gear are clear: improved responsiveness, enhanced performance, and greater user satisfaction.

Customization and Personalization for Users

The ability to customize and personalize fitness equipment has transformed how users engage with their workouts. 3D printing technology enables you to tailor gear specifically to your body type, preferences, and workout style. With this innovative approach, you can create equipment that truly reflects your needs.

By incorporating user feedback into the design process, manufacturers can better understand user preferences and create tailored solutions that enhance your fitness experience. Whether it’s an adjustable weight bench or a unique grip design for dumbbells, every aspect can be modified to suit you.

This level of customization allows for design iterations that improve functionality and comfort, ensuring that your equipment works seamlessly with your routines. Ultimately, 3D printing empowers you to take control of your fitness journey, making each workout more enjoyable and effective. Embracing personalized equipment can lead to better results and a more engaging exercise experience.

Rapid Prototyping and Design Flexibility

With rapid prototyping, designers can quickly create and test new gym equipment concepts, allowing for a more agile development process. This approach enables faster design iterations, guaranteeing the final product meets user needs effectively. Here’s how it enhances flexibility:

- Speedy Adjustments: You can modify designs based on real-time user feedback, making it easy to pivot when something doesn’t work as intended.

- Cost-Effective Testing: Rapid prototyping reduces material waste and costs, letting you experiment without breaking the bank.

- Enhanced Collaboration: It fosters better teamwork; designers and engineers can work closely to refine ideas based on insights from athletes and trainers.

Through these advantages, rapid prototyping not only streamlines the development of gym equipment but also guarantees that the final product is tailored to improve user experience and performance. Embracing this method means you’re always one step ahead in the fitness market.

Sustainable Practices in Manufacturing

As gym equipment design evolves through rapid prototyping, manufacturers are increasingly focusing on sustainable practices to minimize their environmental impact. You’ll find that many companies are now opting for eco-friendly materials, such as bioplastics and recycled metals, which not only reduce the carbon footprint but also enhance the durability of the products. By using these materials, manufacturers can create gym equipment that’s both functional and environmentally responsible.

Additionally, waste reduction is becoming a key priority in the production process. Through 3D printing, manufacturers can produce only what’s necessary, minimizing excess and avoiding traditional manufacturing waste. This method allows for precise designs that meet user needs without the surplus materials typically associated with mass production.

Challenges Facing 3D Printing in the Fitness Industry

When considering 3D printing for gym equipment, you’ll encounter challenges like material limitations and durability issues. These factors can impact the performance and safety of the equipment you’re designing. Additionally, managing regulatory compliance can complicate the process, making it essential to stay informed about industry standards.

Material Limitations and Durability

Although 3D printing offers innovative solutions for gym equipment design, it faces significant challenges regarding material limitations and durability. To guarantee effective use in fitness applications, you should consider:

- Material strength: Many 3D printed materials struggle to match the strength of traditionally manufactured components, raising concerns about safety during intense workouts.

- Longevity: Some materials degrade faster under continuous stress and exposure to sweat, demanding frequent replacements and increasing costs.

- Manufacturing processes: Not all 3D printing methods yield consistent quality, potentially compromising the durability of gym equipment.

Addressing these issues is essential for the fitness industry to fully harness the potential benefits of 3D printing and deliver reliable, long-lasting products.

Regulatory Compliance Challenges

Maneuvering the regulatory landscape is essential for companies looking to integrate 3D printing into gym equipment development. You’ll face numerous challenges regarding regulatory standards, which vary widely across regions and markets. Ensuring that your products meet these standards is vital for gaining consumer trust and avoiding legal issues. Compliance testing can be another hurdle, as it often requires specific methodologies that might not align perfectly with 3D printing processes. This inconsistency can lead to delays and increased costs, making it important to stay updated on evolving regulations. By addressing these compliance challenges proactively, you can streamline your development process and enhance market acceptance of your innovative gym equipment.

Case Studies of Innovative 3D Printed Equipment

As the fitness industry increasingly embraces technological advancements, innovative 3D printed gym equipment is revolutionizing how we approach training. These 3D fitness innovations are creating custom weightlifting solutions that cater to individual needs, enhancing performance and safety.

Here are three notable case studies:

- Personalized Dumbbells: A startup developed dumbbells tailored to a user’s grip and strength level, ensuring ideal performance and comfort.

- Adjustable Resistance Bands: Another company created bands with customizable resistance levels, allowing users to adapt their workouts easily without changing equipment.

- Ergonomic Kettlebells: A design team printed kettlebells with unique shapes that reduce strain on the wrist, promoting safer lifting techniques.

These examples show how 3D printing not only fosters innovation but also transforms traditional gym equipment into personalized, effective tools for all fitness enthusiasts.

The Future of 3D Printing in Gym Equipment Development

As you consider the future of 3D printing in gym equipment, think about the incredible potential for customization and personalization. This technology not only allows for tailored designs that meet individual needs but also offers cost-effective solutions for prototyping. With these advancements, the way we develop and interact with fitness equipment could transform dramatically.

Customization and Personalization

Customization and personalization are transforming the landscape of gym equipment development, making it possible for fitness enthusiasts to tailor their gear to meet individual needs and preferences. With 3D printing, you can achieve a level of ergonomic design that wasn’t possible before. Here are three ways customization enhances your workout experience:

- Fit and Comfort: You can create equipment that perfectly matches your body, ensuring maximum comfort during workouts.

- Style and Aesthetics: Choose colors and designs that resonate with your personal style, making your gym gear uniquely yours.

- Functionality: Modify features based on your user preferences, whether you need specific grips or adjustable components.

This evolution not only enhances your fitness journey but also promotes greater engagement and motivation.

Cost-Effective Prototyping Solutions

While the initial investment in 3D printing technology may seem intimidating, the cost-effective prototyping solutions it offers are revolutionizing the development of gym equipment. You’ll find that 3D printing facilitates affordable innovation, enabling designers to create and test prototypes without hefty costs. This leads to enhanced design efficiency, allowing for quicker iterations and improvements.

| Prototype Type | Traditional Method Cost | 3D Printing Cost |

|---|---|---|

| Weight Bar | $500 | $150 |

| Dumbbell | $300 | $75 |

| Resistance Band | $200 | $50 |

| Bench Press | $800 | $200 |

With these savings, you can allocate resources to further enhance your gym equipment, pushing the boundaries of creativity and functionality.

Frequently Asked Questions

What Materials Are Commonly Used in 3D Printing Gym Equipment?

When it comes to 3D printing gym equipment, you’ll find a variety of materials commonly used. Biodegradable plastics are becoming popular due to their eco-friendly properties, making them a great choice for sustainable designs. Additionally, composite materials are often utilized for their strength and durability, ensuring that the equipment can withstand heavy use. By choosing the right materials, you can create innovative and functional gym equipment that meets both performance and environmental standards.

How Does 3D Printing Impact the Cost of Gym Equipment?

3D printing greatly impacts the cost of gym equipment by enabling cost reduction and enhancing production efficiency. You’ll find that manufacturers can create customized designs at a lower cost than traditional methods, minimizing waste and labor expenses. Plus, the ability to quickly produce prototypes allows for faster iterations and adjustments, leading to better products without breaking the bank. Overall, 3D printing makes high-quality gym equipment more accessible and affordable for everyone.

Can 3D Printed Equipment Withstand Heavy Usage?

Imagine a gym where equipment withstands the intensity of a thousand workouts without breaking a sweat! You’ll find that 3D printed gear can indeed hold up under heavy usage. Through rigorous durability testing, it’s engineered to endure various usage scenarios, from explosive weightlifting to relentless cardio sessions. While the material choices matter, many 3D printed options are surprisingly robust, making them a viable contender for even the most demanding fitness enthusiasts.

What Are the Safety Concerns With 3D Printed Gym Gear?

When considering safety concerns with 3D printed gym gear, durability testing is vital. You’ll want to guarantee that the equipment can handle regular use without breaking down. Additionally, gathering user feedback is essential; it helps identify potential issues that might not be apparent during testing. By prioritizing these factors, you can ensure that the gym gear not only meets safety standards but also provides a reliable experience for users in their workouts.

How Long Does It Take to Produce 3D Printed Equipment?

When you’re looking at production timelines for 3D printed equipment, it can vary considerably based on complexity and size. Typically, smaller items can be ready in hours, while larger pieces might take days. One of the great perks is design flexibility; you can tweak designs easily without lengthy retooling processes. This means you can iterate quickly, testing new concepts and improving functionality faster than traditional manufacturing methods allow.